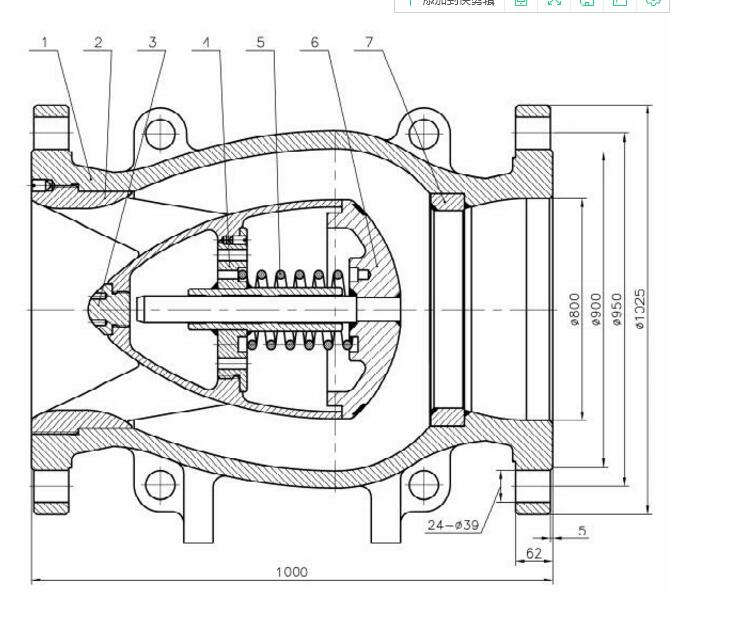

Features of ZLH41H Venturi Check valve

1. The valve consists of a valve body, a fluid guide, an axial movement flap and a spring element. The valve can effectively prevent the back flow of the media. Ensure pipeline safety.

2. The valve body, valve disc, and tail vertebrae are designed as streamlined channels with good fluid properties, minimizing flow resistance and pressure.

3. The use of high-performance spring material HT/INCONELX-750, with excellent corrosion resistance, oxidation resistance and excellent mechanical properties, ensures the operating conditions of the spring under long-term working conditions.

4. Silent operation to eliminate noise and water hammer in the valve pipe to ensure the safety of equipment and pipelines.

5. The rapid response of opening and closing, highly reliable preload springs allow the flap to respond quickly to fluid pressure changes.

6. Compact structure, easy installation, vertical and horizontal installation.

7. The valve adopts surfacing welding surface of alloy steel, which is wear-resistant, corrosion-resistant and has long service life.

8. The valve has a wide range of pressures.

.png) Contact Now

Contact Now