Product Description

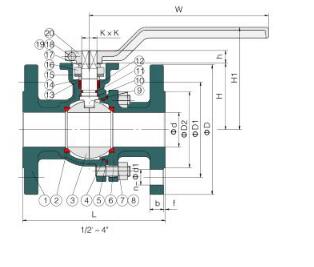

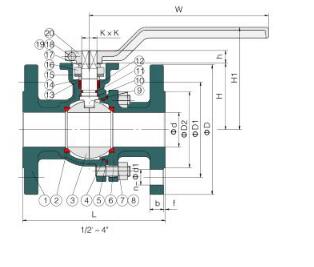

cast steel floating ball valve structural feature

Switch Indication of Hand operated Float Ball Valve

Locking Device

Anti- Blow out of stem

Anti- Static Device

Middle Flange leak-tight structure

Full bore & Reduce bore

1.Indication of valve`s open and close positions

Ball, stem and handle are one assembly unit. The stem head is a flat square structure and the valve is easy tobeseen either in the opened or close position from the place the handle is in. when the handle or the flat square of the stem head is parallel with the pipeline, the valve is in the fully opened or close opened position. While n the fullyclosed one when vertical to the pipeline.

2. Locker

To prevent maloperation of the valve, a hanging lock can be used to lock it when in the fully opened or closed position, which is very important especially for the valve mounted outside or not allowed to be opened or closed by the technological flow.

3. Stem fly-resisting structure

The stem may be pushed out by the pressure in the middle cavity of the body when th medium goes through the valve.To prevent this, a flyresisting structure is made on the lower part of the stem. In this way, even if the packing and /or thrust bearing are burnt out in a fire or damaged by other causes, the medium`s pressure inside of the body will have both stem flange and upper sealing face of body tightly contacted so as to prevent a lot of medium form leaking form the damaged packing place.

4. Electrostatic-proof device and fire-fighting structure

Both electrostatic-proof device and fire-fighting structure and fir-fighting structure are designed. Once the seat ring is burnt out in case of a fire. The ball would be directly contacted with the metal face of the body so as to prevent a lot of the body so as to prevent a lot of medium from leaking from leaking from the burnt place of the seat ring.

5.Unique sealing structure of seat ring

The dual-line seal and the self-combustible pressure discharge able seat ring designed by way of combining the years ball valve manufacturing experience and the foreign advanced know-how can ensure the full seal under a high or low pressure and a vacuum state.

6. Full or reduced diameter

The valve nominal diameter is identical to the inner diameter of the pipeline (which can be reduced one if so required by users ) for the sake of cleaning.

|

NO:

|

PARTS

|

MATERIAL

|

|

1

|

BODY

|

WCB CF8 CF8M

|

|

2

|

SEAT

|

PTEE

|

|

3

|

BALL

|

CF8 CF8 CF8M

|

|

4

|

0-RING

|

FPM

|

|

5

|

GASKET

|

PTEE

|

|

6

|

BONNET

|

WCB CF8 CF8M

|

|

7

|

BOLT

|

304

|

|

8

|

NUT

|

304

|

|

9

|

STEM

|

304 304 316

|

|

10

|

STEM WASHER

|

PTFE+25%GF

|

|

11

|

O-RING

|

FPM

|

|

12

|

PACKING

|

PTEE

|

|

13

|

WEAR WASHER

|

PTEE+25%GF

|

|

14

|

GLAND

|

304

|

|

15

|

DISC SPRING

|

304

|

|

16

|

GLAND FLANGE

|

CF8

|

|

17

|

STOPPER

|

304

|

|

18

|

HEX SOCKET BOLT

|

304

|

|

19

|

NUT

|

304

|

|

20

|

HANDLE

|

WCB/CF8

|

|

21

|

BOLT

|

304

|

|

22

|

NUT

|

304

|

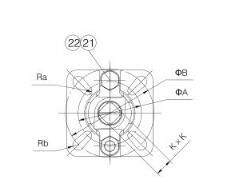

Dimensions CLASS150

|

Nominal Diameter

|

L

|

d

|

D2

|

D1

|

D

|

b

|

f

|

n-Φd1

|

H

|

h

|

H1

|

W

|

Ra

|

Rb

|

A

|

B

|

KxK

|

|

15

|

1/2"

|

108

|

15

|

35

|

60.3

|

90

|

10

|

2

|

4-16

|

55

|

9

|

87

|

140

|

3.0

|

3.5

|

36

|

50

|

9x9

|

|

20

|

3/4"

|

117

|

20

|

43

|

69.9

|

100

|

10.5

|

2

|

4-16

|

60

|

9

|

92

|

140

|

3.0

|

3.5

|

36

|

50

|

9x9

|

|

25

|

1"

|

127

|

25

|

51

|

79.4

|

110

|

10.5

|

2

|

4-16

|

67

|

11

|

102

|

170

|

3.0

|

3.5

|

42

|

50

|

11x11

|

|

32

|

1-1/4"

|

140

|

32

|

63.5

|

88.9

|

115

|

11.2

|

2

|

4-16

|

76

|

11

|

111

|

170

|

3.0

|

3.5

|

42

|

50

|

11x11

|

|

40

|

1-1/2"

|

165

|

40

|

73

|

98.4

|

125

|

12.7

|

2

|

4-16

|

85

|

14

|

123

|

200

|

3.5

|

4.5

|

50

|

70

|

14x14

|

|

50

|

2"

|

178

|

50

|

92

|

120.7

|

150

|

14.3

|

2

|

4-19

|

93

|

14

|

131

|

200

|

3.5

|

4.5

|

50

|

70

|

14x14

|

|

65

|

2-1/2"

|

190

|

65

|

105

|

139.7

|

180

|

15.9

|

2

|

4-19

|

113

|

17

|

157

|

300

|

4.5

|

5.5

|

70

|

102

|

17x17

|

|

80

|

3"

|

203

|

80

|

127

|

152.4

|

190

|

17.5

|

2

|

4-19

|

126

|

17

|

170

|

300

|

4.5

|

5.5

|

70

|

102

|

17x17

|

|

100

|

4"

|

229

|

100

|

157

|

190.5

|

230

|

22.3

|

2

|

4-19

|

141

|

17

|

185

|

300

|

4.5

|

5.5

|

70

|

102

|

17x17

|

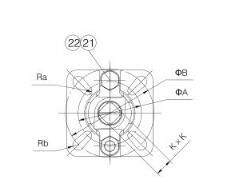

Dimensions CLASS 300

|

Nominal Diameter

|

L

|

d

|

D2

|

D1

|

D

|

b

|

f

|

n-Φd1

|

H

|

h

|

H1

|

W

|

Ra

|

Rb

|

A

|

B

|

KxK

|

|

15

|

1/2"

|

140

|

15

|

35

|

66,7

|

95

|

12.7

|

2

|

4-16

|

55

|

9

|

87

|

140

|

3.0

|

3.5

|

36

|

50

|

9x9

|

|

20

|

3/4"

|

152

|

20

|

43

|

82.6

|

115

|

14.3

|

2

|

4-16

|

60

|

9

|

92

|

140

|

3.0

|

3.5

|

36

|

50

|

9x9

|

|

25

|

1"

|

165

|

25

|

51

|

88.9

|

125

|

15.9

|

2

|

4-16

|

67

|

11

|

102

|

170

|

3.0

|

3.5

|

42

|

50

|

11x11

|

|

32

|

1-1/4"

|

178

|

32

|

63.5

|

98.4

|

135

|

17.5

|

2

|

4-16

|

76

|

11

|

111

|

170

|

3.0

|

3.5

|

42

|

50

|

11x11

|

|

40

|

1-1/2"

|

190

|

40

|

73

|

114.3

|

155

|

19.1

|

2

|

4-16

|

85

|

14

|

123

|

200

|

3.5

|

4.5

|

50

|

70

|

14x14

|

|

50

|

2"

|

216

|

50

|

92

|

127

|

165

|

20.7

|

2

|

4-19

|

93

|

14

|

131

|

200

|

3.5

|

4.5

|

50

|

70

|

14x14

|

|

65

|

2-1/2"

|

241

|

65

|

105

|

149.2

|

190

|

23.9

|

2

|

4-19

|

113

|

17

|

157

|

300

|

4.5

|

5.5

|

70

|

102

|

17x17

|

|

80

|

3"

|

282

|

80

|

127

|

168.3

|

210

|

27

|

2

|

4-19

|

126

|

17

|

170

|

300

|

4.5

|

5.5

|

70

|

102

|

17x17

|

|

100

|

4"

|

305

|

100

|

157

|

200

|

255

|

30.2

|

2

|

4-19

|

141

|

22

|

226

|

650

|

4.5

|

5.5

|

70

|

102

|

22x22

|

Bob Zheng (sales manager)

Ningbo RMI Plastic Co.,Ltd

Tel:+86-574-86865705

Fax:+86-574-86865705

http://www.rmiplast.com/

.png) Contact Now

Contact Now