Product Description

The back pressure valve is operated by the elastic force of the built-in spring: when the pressure of the system is higher than the set pressure, the diaphragm plugging the pipe under the spring force of spring; when the pressure of the system is larger than the set pressure, the diaphragm is compressed, the pipe is connected, and the liquid passes through the back pressure valve. The structure of the back pressure valve is similar to that of the check valve, but the opening pressure is greater than the check valve, between 0.2 and 1.6 MPa.

Under the condition of unstable pressure of pipeline or equipment container, the back pressure valve can maintain the pressure required by the pipeline, so that the pump can output the flow normally. At the end of the pump, the siphon phenomenon often occurs due to gravity or other functions. At this time, the back pressure valve can reduce the fluctuation of the flow and pressure caused by siphon. For metering pumps and other volumetric pumps, there will be excessive transportation when working under low system pressure. In order to prevent similar problems, the outlet of the metering pump must have at least 0.7Bar back pressure. The purpose is to install the back pressure valve at the outlet of the metering pump.

When selecting backpressure valves, the parameters and data must be determined.

1, the caliber of the required backpressure valve is usually the outlet diameter of the pump.

2. The range of pressure required to be set;

3. What kind of material is needed? Generally speaking, it is considered from the nature and temperature of the fluid conveyed. Conventional materials are: PVC, 304, 316, 316L stainless steel, carbon steel, etc.

4, import and export connection mode, this general requirement is less. However, in some systems, such as food and drinking water production systems, some pipelines may have special requirements for connection. Common connections include internal thread, flange and hose connection.

Product Features of Back Pressure Valve:

1, Compact structure and stable performance

2, Easy installation and debugging

3, Sensitive reaction and good reproducibility

4, Selective large size range DN10mm DN100mm

5, Small pressure difference by specially designed flow structure to avoid forming a closure

6, Easy to set the working pressure by regulating device

7, Installed in the bypassas overflow valve use

8, Used as anti siphon valve to prevent gravity under static conditions.

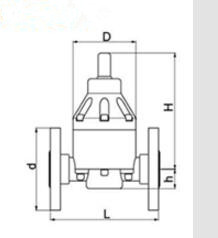

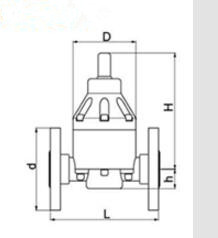

|

MODEL

|

STAND

|

L

|

D

|

H

|

h

|

d

|

|

18615

|

DN15

|

128

|

82

|

181

|

27

|

95

|

|

18620

|

DN20

|

130

|

82

|

181

|

29

|

105

|

|

18625

|

DN25

|

158

|

107

|

198

|

33

|

115

|

|

18632

|

DN32

|

180

|

107

|

198

|

35

|

140

|

|

18640

|

DN40

|

220

|

155

|

260

|

60

|

150

|

|

18650

|

DN50

|

235

|

155

|

260

|

60

|

165

|

|

18665

|

DN65

|

238

|

155

|

260

|

65

|

185

|

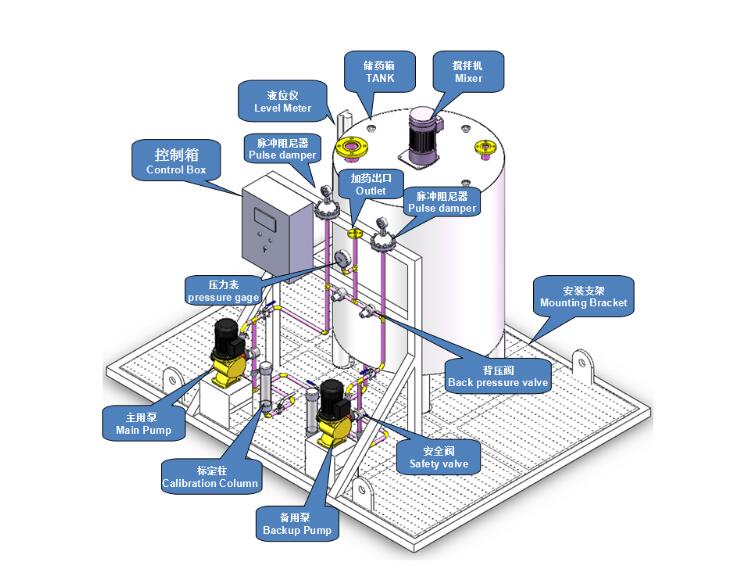

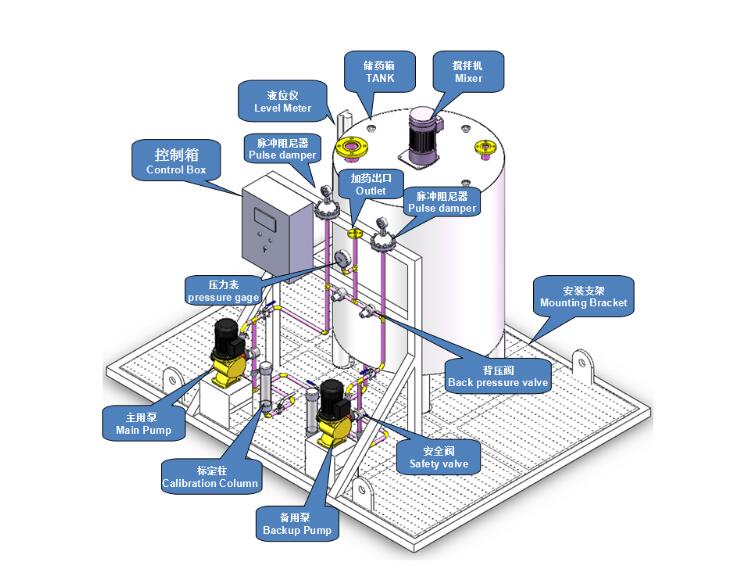

application

.png) Contact Now

Contact Now